Introduction

High temperature power cables play a crucial role in various industries where extreme heat conditions are prevalent. These specialized cables are designed to withstand elevated temperatures, ensuring reliable and safe transmission of power in demanding environments. In this article, we will explore the significance of high temperature power cables, their construction, applications, and the key factors to consider when selecting the right cable for specific industrial needs.

The Importance of High Temperature Power Cables

In industries such as steel manufacturing, petrochemical plants, and power generation facilities, high temperatures are a common occurrence. Traditional power cables are not suitable for such environments as they are prone to degradation and failure when exposed to extreme heat. High temperature power cables are specifically engineered to withstand these challenging conditions, providing a reliable and efficient means of transmitting power.

One of the primary advantages of high temperature power cables is their ability to maintain their electrical and mechanical properties even at elevated temperatures. This ensures uninterrupted power supply and prevents costly downtime in industrial operations. Additionally, these cables offer enhanced fire resistance and durability, making them a preferred choice for critical applications where safety and reliability are paramount.

Construction of High Temperature Power Cables

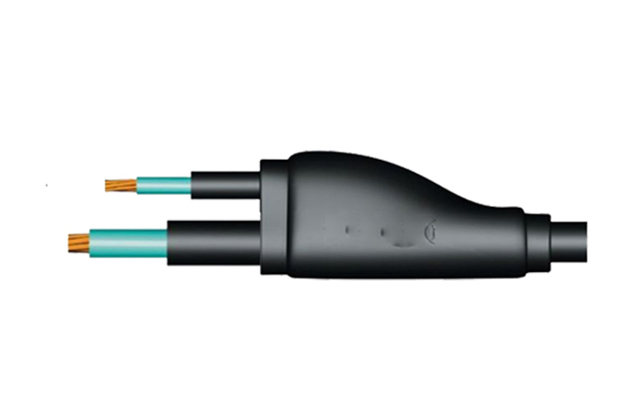

High temperature power cables are manufactured using specialized materials and construction techniques to ensure their performance in extreme heat environments. The key components of these cables include:

1. https://www.jiangyuancables.com/fixed-laying-of-pvc-insulated-flexible-wires/ : The conductor of a high temperature power cable is typically made of copper or aluminum to provide excellent electrical conductivity. These conductors are designed to withstand high temperatures without losing their structural integrity or conductivity.

2. Insulation: The insulation material used in high temperature power cables is crucial for maintaining electrical insulation and protecting the conductor from heat damage. Common insulation materials for high temperature cables include silicone rubber, fluoropolymers, and mica tape, which offer exceptional heat resistance and dielectric strength.

3. Jacketing: The outer jacket of a high temperature power cable provides mechanical protection and resistance to abrasion, chemicals, and environmental factors. Depending on the application, jacketing materials such as fiberglass, PVC, or Teflon may be used to ensure the cable's durability and longevity.

4. Shielding: In some high temperature power cables, shielding layers are incorporated to protect against electromagnetic interference (EMI) and radio frequency interference (RFI). Shielding can be achieved using materials like aluminum foil, copper braid, or conductive polymers to maintain signal integrity in sensitive applications.

Applications of High Temperature Power Cables

High temperature power cables find wide-ranging applications across various industries where heat resistance and reliability are critical. Some common applications of these cables include:

1. Steel Industry: In steel manufacturing plants, high temperature power cables are used to power electric arc furnaces, induction heating systems, and other high-temperature equipment. These cables are designed to withstand the extreme heat generated during the steelmaking process, ensuring uninterrupted power supply.

2. Petrochemical Plants: Petrochemical facilities require high temperature power cables to power equipment such as heaters, boilers, and pumps that operate at elevated temperatures. These cables are essential for maintaining the safety and efficiency of the plant's operations.

3. Power Generation: In power plants, high temperature power cables are used to connect generators, transformers, and switchgear systems that operate in environments with high thermal loads. These cables play a crucial role in transmitting power from the generation source to distribution networks.

4. Aerospace and Defense: High temperature power cables are also utilized in aerospace and defense applications where extreme heat and harsh environmental conditions are prevalent. These cables are crucial for powering avionics systems, missile defense systems, and other military equipment.

Key Factors to Consider When Selecting High Temperature Power Cables

When choosing high temperature power cables for specific industrial applications, several factors need to be considered to ensure optimal performance and safety. Some key factors to keep in mind include:

1. Temperature Rating: The temperature rating of a high temperature power cable indicates the maximum temperature at which the cable can operate safely without degradation. It is essential to select a cable with a temperature rating that exceeds the operating temperature of the application to prevent overheating and potential failure.

2. Insulation Material: The choice of insulation material is critical in high temperature power cables as it determines the cable's heat resistance, flexibility, and durability. Silicone rubber and fluoropolymers are commonly used for high temperature applications due to their excellent thermal properties and resistance to chemicals and abrasion.

3. Voltage Rating: High temperature power cables come in various voltage ratings to accommodate different power distribution requirements. It is essential to select a cable with the appropriate voltage rating to ensure safe and reliable power transmission without risk of electrical breakdown.

4. Flexibility: In applications where cable flexibility is essential, such as in tight spaces or moving machinery, choosing a high temperature power cable with flexible construction is crucial. Flexible cables are easier to install and maneuver, reducing the risk of damage or premature wear.

5. Environmental Conditions: Consideration should be given to the environmental conditions in which the high temperature power cable will be installed. Factors such as exposure to chemicals, moisture, UV radiation, and mechanical stress can impact the cable's performance and longevity.

Conclusion

High temperature power cables are indispensable components in industries where extreme heat conditions are prevalent. These specialized cables are designed to withstand high temperatures, ensuring reliable power transmission and safety in demanding environments. By understanding the construction, applications, and key factors to consider when selecting high temperature power cables, industries can optimize their operations and minimize the risk of downtime and equipment failure. Investing in high quality and properly specified high temperature power cables is essential for maintaining operational efficiency and ensuring the safety of industrial processes.